This product is made by sintering copper paste with tiny particle size, which has excellent resistivity and reliability. By adding high temperature binder and special filler, the coefficient of thermal expansion of hole copper and interface can be further adjusted to achieve highly reliable hole metallization.

Process Flow:

High Efficiency, Good Quality & Low Cost Of Plugging Process:

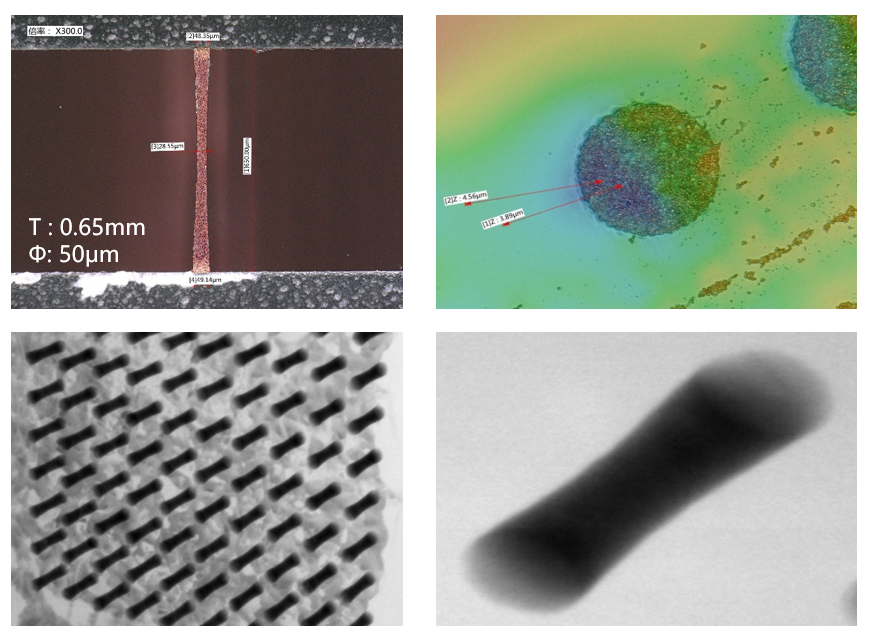

• Achieve high thickness to diameter ratio of small aperture low resistance conduction

• High reliability adhesion of hole copper and interface layer with low coefficient of thermal expansion

• Resistant to conventional chemical corrosion, thermal stress resistance, good weldability

• It can carry out chemical etching, surface treatment and other reprocessing processes normally and is stable and reliable

• Passed the 300°C thermal shock test, no failure after 1000 thermal cycles, and the adhesion is still stable

Technlogy Advantages:

• Green environmental protection, reducing the traditional sputtering and electroplating large-scale equipment and capital investment

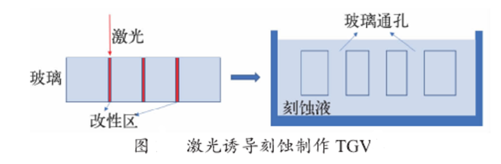

• The process is simple, and the glass through-hole TGV metallization is achieved by filling the conductive metal paste by printing

• Good adhesion, glass through-hole TGV metal paste contains glass powder, which improves the adhesion between metal and glass

• It can realize the metallization of glass through-hole TGV holes with high thickness to diameter ratio, and the maximum plug hole thickness to diameter ratio is as high as 20:1

• The process is convenient, the processing cycle is short, and it+ can be achieved in only three steps of printing + sintering + grinding

Specification:

| Medium aluminum glass | High aluminum glass | Borosilicate glass | Quartz glass |

|

|

|

|

|

Coefficient of Thermal Expansion | 7ppm/℃ | 5ppm/℃ | 3.5ppm/℃ | 0.5ppm/℃ |

Softening Point | ∽500℃ | ∽600℃ | ∽800℃ | ∽1700℃ |

Size | <250mmX350m | <250mmX350m | <250mmX350m | <250mmX350m |

Thickness | 0.25∽2mm | 0.25∽2mm | 0.2∽1mm | 0.1∽1mm |

Aperture | 0.03∽1mm | 0.03∽1mm | 0.02∽1mm | 0.02∽1mm |

Depth-to-diameter Ratio | <20:1 | <20:1 | <20:1 | <20:1 |

Application:

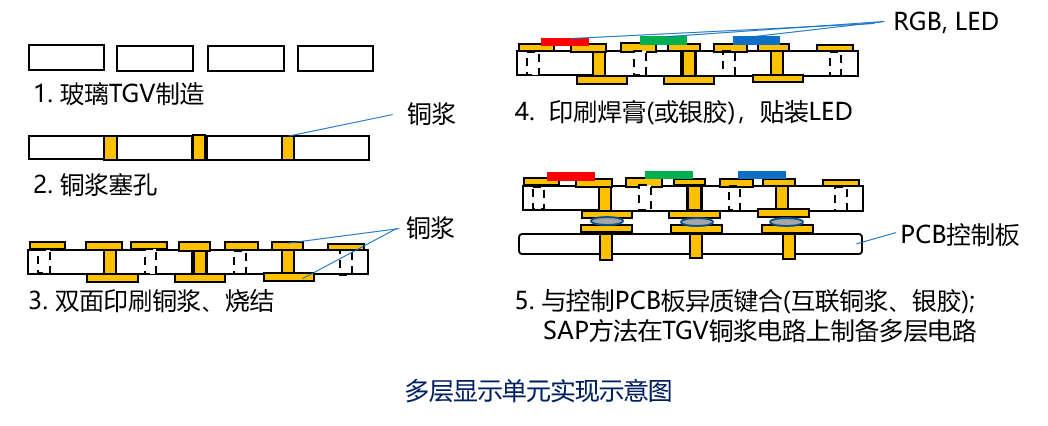

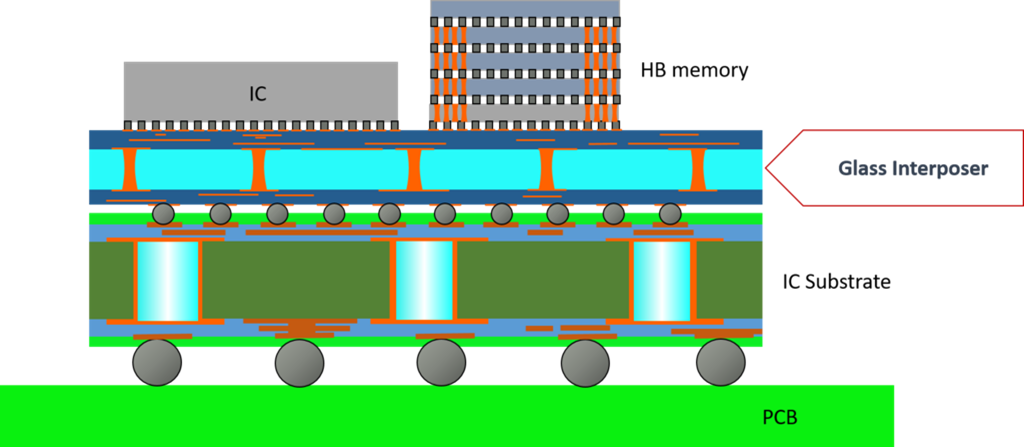

Glass through-hole TGV has broad application prospects, TGV can be used in optical communication, RF module, optoelectronic system integration, MEMS packaging, electronic gas amplifier, equipment fixture, medical equipment and other fields. In the glass through-hole TGV, the plug hole copper paste can be heterogeneously interconnected with the metal of the package substrate or PCB board, so as to realize multi-dimensional packaging.

Processing Performance: